Quick disconnect couplings are mechanical devices used to swiftly join fluid transfer lines. They also go by many other names, including quick disconnect fittings, quick release fittings, quick disconnects, quick release couplings, quick connect couplings, quick couplings, and breakaway couplings. Read More…

Triumph designs, engineers, manufactures, repairs and overhauls a broad portfolio of aerostructures, aircraft components, accessories, subassemblies and systems. We have developed an exclusive line of Hydraulic Quick Disconnect Couplings, which are standard equipment with virtually every major commercial airline and airframe manufacturer in the free world.

Kent Rubber Supply has been a trusted supplier of industrial couplings and fittings since 1946. Offering all of the connections that you need for your industrial fitting, securement, accessories, and industrial coupling needs. Using our up-to-date assembly process, we can confidently supply all your coupling and fitting solutions.

When it comes to quick release couplings we are your experts! Since our establishment we have provided products and services to a global market. Our skilled engineers will work with you from design to delivery to ensure that you are receiving a product that will fit your exact specifications. To learn more about what we may be able to do for you; get in touch with us on the web or by telephone...

Nudraulix manufactures a full line of quick disconnect couplings, quick connect couplings and hydraulic couplings for air, water and steam from 1/8"-2" sizes. For over 40 years, we have been providing products to numerous industries such as shipping, machinery and fluid delivery systems, as well as oil and natural gas utilities. Contact us today and make us your number one source!

Established in 1985, we have been providing our customers with quick release couplings that provide a lasting value. Our products use the latest technology to ensure a product that will maximize productivity and efficiency for your company! There is no job too large or too small for us to handle! To learn more about how we may be able to benefit you; get in touch with our customer service...

More Quick Disconnect Manufacturers

Applications

Fluids with which quick disconnects commonly work include air, chemicals, fuel, gas, hydraulic fluids, oil, solid transfer, steam, and water. Quick disconnects are simple products, but they are important to all applications that could potentially require an easy and fast solution to fluid spillage or mingling.

Efficient flow applications and products that quick disconnect couplings serve include agricultural sprayers, automotive systems, chemical and food processes, shut-off valves, ball valves, construction, fire fighting hoses, and gas transfer.

Safety applications in which quick disconnect couplings are key include those in the aerospace, fuel, and first response industries. For instance, because aircraft fuel is extremely combustible, aircraft fuel tank hoses are all equipped with dry disconnect couplings; they reduce spillage that could lead to fires or fume inhalation. Quick disconnect couplings are important to emergency service applications including emergency decontamination, emergency oxygen supply, and firefighting.

History

The first quick disconnect coupling products were commissioned by various governments for the military during World War II. They wanted couplings that they could apply and remove more easily than pneumatic couplings. Those pneumatic couplings that they used before not only had to be applied and removed with tools, but they were also stubborn and slowed down service people and their use of vehicles and equipment.

After the war, manufacturers realized the general usefulness of quick disconnect couplings and expanded their use. Today, manufacturers use quick disconnect couplings for a diverse set of applications, from connecting garden hoses to connecting oxygen lines.

Design

Materials

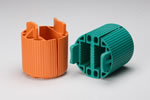

Manufacturers select coupling fabrication materials based on the types of liquids they will be helping transport and the application details in general. Some of the materials available for coupling fabrication include metals like carbon steel, stainless steel, copper, brass, nickel-plated brass, bronze, and aluminum. For higher flow applications, manufacturers often select stainless steel. Manufacturers also offer quick disconnect couplers made from a variety of plastics. While manufacturers make the majority of couplings from metal, they are starting to make more and more from plastic. Plastic couplings are becoming more popular because they cost less to make and exhibit excellent corrosion resistance.

Considerations and Customization

When designing or assigning quick disconnect couplings, manufacturers think about a number of things, including application temperature range, application pressure (psi) range, application fluid flow type, flow line diameter, and frequency of use. In addition to offering quick release couplings equipped with the ability to handle a wide range of high temperatures and high flow psi, manufacturers also offer couplings equipped to assist fluid transfer lines of a wide variety of sizes. Typically, they offer couplings ranging in size from one eighth of an inch to ten inches in diameter. Also, to make them more effective, manufacturers sometimes safe-tie quick connect disconnect couplings with wire.

How They Work

Quick disconnects are usually operated manually instead of automatically because many machines cannot not be programmed to respond to an unexpected change. Most, however, only require the use of one hand. Plus, operators do not need the assistance of tools, though some older models are still operated with a wrench.

To perform connecting and disconnecting actions, operators turn an interlock mechanism, such as a nut. Generally speaking, to connect a quick disconnect coupling, an operator pulls back a female fitting end and pushes it onto the male end of a hose or tool with at least one valve. Then, to complete the connection, the fittings releases, thus activating the coupling, opening the valve, and allowing fluid to pass through in both directions. When an operator disconnects the coupling, a spring pulls the valve shut, stopping anything from coming or going.

The fact that the system shuts down almost immediately after the coupling is disconnected is an important feature of quick disconnect couplings. Without such expediency, a system leak could rapidly become a large problem.

Types

Quick release couplings are made in a variety of different configurations, in order to accommodate their many applications.

Quick release coupling types include plain connectors, sleeve and poppet couplings, single-poppet connectors, double-poppet connectors, sliding ball couplers, hydraulic quick disconnects, air quick couplers, breakaway couplers, dry disconnect couplings, ball couplers, and camlock couplings.

Plain connectors, as their name implies, are the simplest and least expensive type of quick coupling. They connect the female and male with the assistance of a ball-bearing sleeve lock.

Sleeve and poppet couplings allow zero fluid loss and do not permit air to enter into a poppet valve system.

Single-poppet connectors, which work well with applications that allow for minor spillage, close off the supply of liquid using a single seal.

Double-poppet couplings use two seals to isolate liquid on both sides, trapping only a negligible amount of fluid between the valves and eliminating the step of collecting or draining the lines of spilled product before disconnecting the coupling.

Sliding seal couplers are used to ensure minimal spillage in hazardous chemical applications. To keep space for potential bacteria and dirt small, they place seals flush to the exposed ends of the male and female halves.

Hydraulic quick disconnects, or hydraulic quick couplings, are a specialized type of disconnect coupling. They are designed to efficiently connect and disconnect fluid lines in hydraulic systems while maintaining fluid pressure and not introducing air.

Air quick couplers are specialized couplings designed to work with air, and in particular to facilitate connections between air compressors and pneumatic tools. In the right setting, they may be called quick air compression fittings. Air quick couplings are of good quality, but because air spillage generally poses a smaller threat, if any, the seals they use are not as tight or as quick as those used by others.

Breakaway couplers are customarily utilized during the transfer of hazardous materials; because they remain open during normal operation but close quickly when faced with excessive force, they minimize product loss and safety hazards.

Dry disconnect couplings are equipped with a device that is a variation on the mechanical internal lock, which prevents accidental openings and releases. In order to release the coupler from the pipe or hose, the valves must be closed and sealed off by identical discs in the male and female halves. They provide drip-free connections where hazardous materials are handled or in sanitary environments.

Ball couplers are couplers that hold flow lines together using balls. When an operator pushes a button, the balls, which are distributed on either or both the female and male bodies, draw in and connect the two halves. Once the balls are in place, the operator can release the button and the two halves will lock in the connected position.

Camlock couplings, also known as cam and groove hose couplings, are couplings used most often with chemical and petroleum flow lines. They feature a female coupler and a male adaptor. The coupler and the adaptor connect via the coupler cam arms and the adaptor grooves. Together, they create a strong gasket seal.

Advantages

Quick disconnect couplings offer several significant advantages over other coupling devices, making them a preferred choice in many industrial applications. One of the primary benefits is their speed and ease of use. As the name suggests, quick disconnect couplings allow for rapid connection and disconnection of fluid or gas lines with minimal effort. This efficiency saves valuable time during equipment setup, maintenance, and repairs, increasing overall productivity.

Another advantage of quick disconnect couplings is their ability to create a secure and reliable connection. When properly engaged, these couplings form a tight seal, preventing leaks and minimizing fluid loss. This feature is especially crucial in applications where fluid containment is critical, such as in hydraulic systems, fuel lines, and medical devices.

Quick disconnect couplings also enhance safety in various industries. Their fast disconnection capability allows operators to isolate equipment and pipelines quickly in case of emergencies or when maintenance is required. This ability to swiftly shut down or isolate parts of a system can help prevent accidents, spills, and hazardous situations, safeguarding both personnel and the environment.

Furthermore, these couplings come in a variety of materials, sizes, and configurations to accommodate diverse applications. Whether used in high-pressure hydraulic systems, pneumatic tools, or fluid transfer lines, there is a quick disconnect coupling designed to meet specific needs. Their versatility makes them adaptable to a wide range of industries, including automotive, aerospace, manufacturing, and agriculture.

Another advantage of quick disconnect couplings is their durability and long-lasting performance. High-quality couplings are often engineered to withstand harsh operating conditions, including extreme temperatures, chemicals, and mechanical stresses. As a result, they have a longer service life, reducing the need for frequent replacements and contributing to cost savings in the long run.

In summary, the advantages of quick disconnect couplings over other coupling devices lie in their speed, ease of use, reliability, safety features, versatility, and durability. Their ability to facilitate rapid connections and disconnections, create secure seals, and accommodate various applications makes them a preferred choice in numerous industrial settings. As technology and materials continue to advance, quick disconnect couplings are likely to remain essential components in optimizing efficiency and safety across diverse industries.

Accessories

Accessories for quick release couplings play a crucial role in enhancing the functionality, safety, and longevity of these couplings in various industries and applications. Some of the key accessories include protective dust caps, protective dust plugs, housings, breakaway clamps, and others.

Protective dust caps and plugs are designed to prevent the ingress of dust, dirt, and other contaminants into the coupling when it is not in use. These contaminants can cause damage to the internal components, reduce the coupling’s efficiency, and lead to premature wear and tear. Therefore, using these protective caps and plugs is essential, especially in outdoor or harsh environments where the coupling is exposed to potential contaminants.

Housings are protective enclosures that provide an extra layer of protection to the entire coupling assembly. They shield the coupling from external impacts, chemical exposure, and adverse environmental conditions. Housings are particularly valuable in applications where the coupling is at risk of being bumped, struck, or exposed to corrosive substances.

Breakaway clamps are safety features that allow the quick release coupling to separate when a certain force or load is applied. This feature is commonly used in applications where there is a risk of equipment damage or injury to operators in case of sudden pulls or excessive force on the coupling. Breakaway clamps help to prevent accidents and minimize potential damage.

Other accessories for quick release couplings may include handles or grip enhancements, which make it easier for operators to connect and disconnect the couplings, especially when wearing gloves or working in challenging conditions.

Determining if you need any of these accessories specifically depends on the specific application and environment in which the quick release coupling will be used. Factors to consider include the operating environment (indoors, outdoors, cleanroom, harsh conditions), potential exposure to contaminants (dust, dirt, chemicals), the possibility of accidental disconnections or impacts, and the ergonomic considerations for ease of use.

For instance, if the coupling will be used outdoors or in dusty environments, protective dust caps and plugs are essential. If the coupling is part of critical machinery or systems and accidental disconnections could have severe consequences, then breakaway clamps may be necessary. Assessing these factors and potential risks will help in determining which accessories are required to ensure the safe and efficient operation of the quick release coupling in your specific application.

In conclusion, accessories for quick release couplings such as protective dust caps, protective dust plugs, housings, breakaway clamps, and others are valuable additions to enhance the functionality, safety, and durability of these couplings in various industrial settings. By carefully evaluating the operating conditions and potential risks, one can determine the specific accessories needed to optimize the performance and reliability of quick release couplings in their application.

Proper Care

To make sure your couplings work well and serve you for a long time, you must first make sure they do not become contaminated when you’re not using them. The best way to do this is by covering them with plugs and caps during disuse.

Next, during use, you need to make sure that you never use a coupling to connect lines that pump higher levels of pressure than that for which the coupling is designed. If you do run fluid lines that exceed high pressure recommendations, the couplings could fail. At best, this would be an inconvenience, and at the worst, this would cause extreme injury, death, or damage to the environment. Likewise, never run fluids through coupled lines that a coupling is not designed to handle. For example, if your coupling is made from a material that cannot handle chemicals without corrosion, do not use it to connect lines that transport such chemicals.

Finally, we also recommend that, in addition to exercising common sense, any coupling operators familiarize themselves with the safety guide your supplier provides.

Standards

Almost universal is the requirement that quick disconnect couplings meet the appropriate ISO (International Standards Organization) standards. ISO puts out standard series related to a number of different quick disconnect coupling types, such as hydraulic couplings, cylindrical couplings, etc. Examples of common ISO series include ISO 7241 series A, ISO 7241 series B, both which deal with hydraulic quick disconnect couplers. ISO series are interchangeable with a number of series offered by prominent companies. Examples include Snap-Tite 72 series, Hansen HK series, Safeway S10 series, Parker 74 series, and Parker 60 series. ISO also offers guidelines related to dimensional requirements.

In addition to ISO, you need to make sure that your quick disconnect fittings meet the standards required per your location, industry and application. To find out what those might be, reach out to your industry leaders.

Things to Consider

The best way to get a set of quick disconnect fittings that work for you is by connecting with a coupling supplier with your best interests in mind. Find a supplier like this by checking out those we have listed on this page; every manufacturer we have listed has a record of excellence. Of course, just because a manufacturer is great for someone else does not mean that they are great for you. To discern between them, we recommend you start by putting together a specifications list that details not only your application requirements, but your project allowances, such as budget and delivery deadline. Once you’ve put your list together, you can browse ours. Based on your specifications, pick out three or four quick disconnect coupling manufacturers in which you’re most interested. Then, contact each of them to discuss your project with a customer service representative. Take notes and/or request they email you a summary of the conversation with a quote. Finally, compare and contrast your conversations and pick the manufacturer you believe will best serve you. Happy hunting!

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services