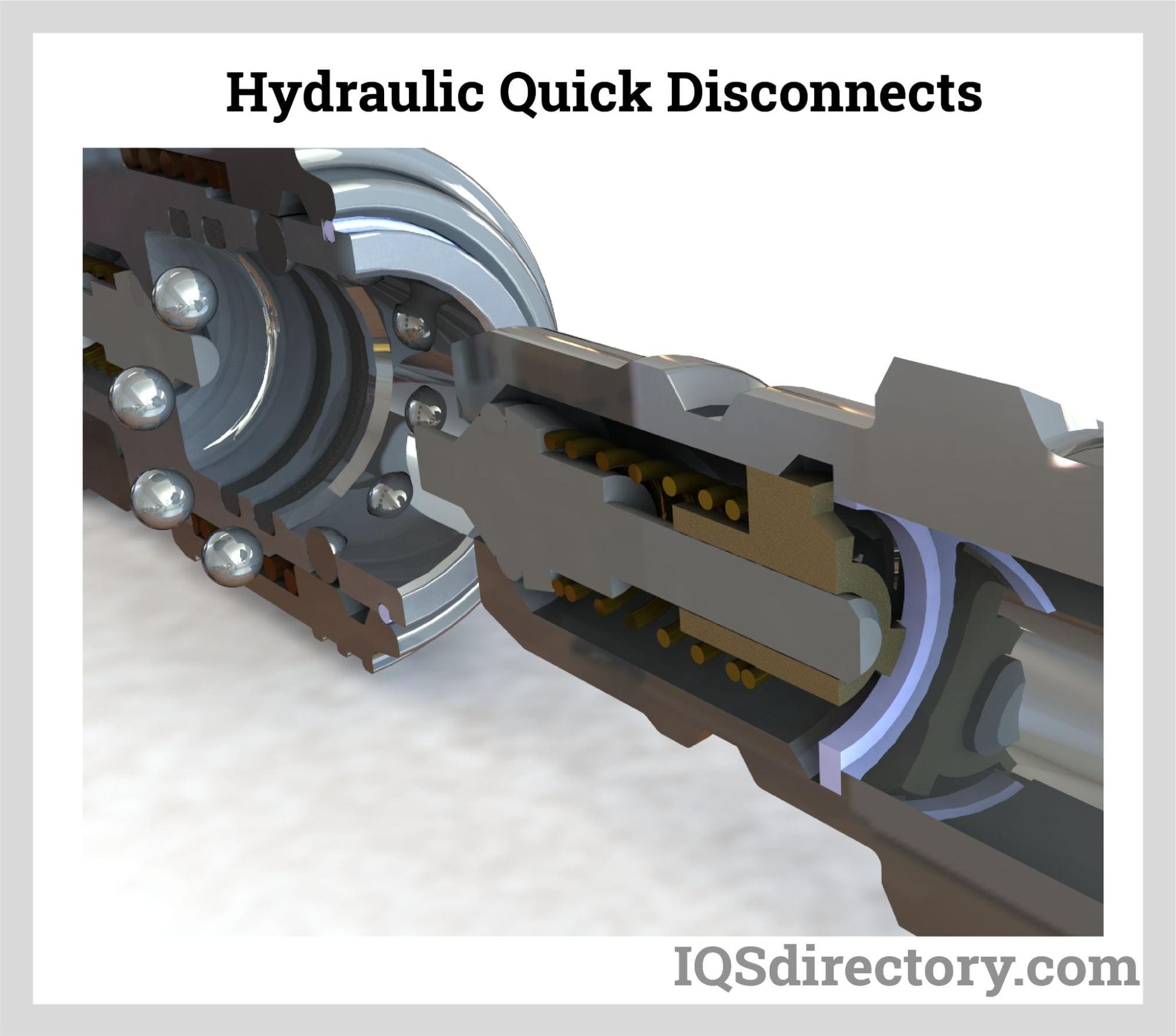

The use of quick disconnect can hasten the installation of hydraulic and pneumatic lines. The male and female halves (nipple and coupler) of a quick disconnect combine to produce a complete coupling. Usually made of metal, coupling halves consist of a body, a latching mechanism, an end connection, and a valving mechanism. Read More…

Triumph designs, engineers, manufactures, repairs and overhauls a broad portfolio of aerostructures, aircraft components, accessories, subassemblies and systems. We have developed an exclusive line of Hydraulic Quick Disconnect Couplings, which are standard equipment with virtually every major commercial airline and airframe manufacturer in the free world.

Kent Rubber Supply has been a trusted supplier of industrial couplings and fittings since 1946. Offering all of the connections that you need for your industrial fitting, securement, accessories, and industrial coupling needs. Using our up-to-date assembly process, we can confidently supply all your coupling and fitting solutions.

When it comes to quick release couplings we are your experts! Since our establishment we have provided products and services to a global market. Our skilled engineers will work with you from design to delivery to ensure that you are receiving a product that will fit your exact specifications. To learn more about what we may be able to do for you; get in touch with us on the web or by telephone...

Nudraulix manufactures a full line of quick disconnect couplings, quick connect couplings and hydraulic couplings for air, water and steam from 1/8"-2" sizes. For over 40 years, we have been providing products to numerous industries such as shipping, machinery and fluid delivery systems, as well as oil and natural gas utilities. Contact us today and make us your number one source!

Established in 1985, we have been providing our customers with quick release couplings that provide a lasting value. Our products use the latest technology to ensure a product that will maximize productivity and efficiency for your company! There is no job too large or too small for us to handle! To learn more about how we may be able to benefit you; get in touch with our customer service...

More Quick Disconnect Manufacturers

The most widely used material is carbon steel, but due to its ability to resist corrosion, brass and stainless steel are also frequently utilized. The distinction between the male and female halves of rapid disconnects is among its most perplexing features. Users frequently think of males as having external threads and females as having internal threads while working with hydraulics threads.

Where to use Quick Disconnects

Quick disconnects are frequently used when the goals listed below are desired outcomes:

Easiest Way to Connect

Quick couplers provide a more practical and secure alternative to reinstalling hose-end connectors if a system necessitates the frequent joining of lines. This is true of equipment used in the field, where tools are not always available. Additionally, some threads, like NPT, ought to only be used once. Failure to comply could lead to catastrophic failure or leaky end-connections. One may avoid needless leaks and expedite installation by using fast couplings because they are made to be reused.

Prevention of Spills

If one ever handled hydraulic oil, transmission fluid, or other chemicals, they would definitely concur that the last place anyone wants that media to be is on the ground, or worse still, on an operator or mechanic. This material is not only potentially harmful, but it is frequently expensive as well. Hydraulic system leaks can affect the functionality of the equipment and necessitate lengthy downtime to locate and resolve. In residential areas, cleanup fees can be quite expensive and result in fines. One can reduce leakage during line changes and prevent downtime based on their choice of quick disconnects.

Applications of Quick Disconnects

Quick disconnects can be combined with hydraulic or pneumatic lines in almost any application because of their adaptability. They are frequently seen on truck and trailer applications, air lines, pressure washing systems, hydraulic attachments, and agricultural machinery.

Machines for Producing Semiconductors

Chemicals, de-ionized water, gases, heat transfer fluids, and frequently the utilization of pneumatics and vacuum are all used during the semiconductor manufacturing process. In the protracted manufacturing and testing procedures used to convert a silicon wafer into finished IC (integrated circuit) chips, there are additional stringent temperature and pressure requirements. The equipment used to handle fluids must be extremely dependable, fluid-compatible, robust, quick, and leak-free.

Hydraulic And Pneumatic Tools And Compressors

Quick disconnects are perhaps most commonly used on pneumatic and hydraulically powered tools and equipment. One may have noticed a rapid disconnect at the end of the fluid lines if they have ever been to an auto repair shop or closely observed a snow plow. Quick disconnects make switching between tools simple.

Food Packaging Apparatus

The food packaging industry places a premium on the uptime of the packaging equipment. When machinery is out for repairs, money is lost. Packaging machinery frequently operates continuously with a user or service professional standing close by to ensure flawless operation. Quick disconnects make quick changeovers possible for the operators, reducing downtime and fluid leakage. The operator can maximize machine uptime and revenue for the business with the aid of quick disconnects.

Detectors for Gas

For safety reasons, it is vital to sample the surrounding air before a worker enters a confined space like a manhole or mine shaft. Long sample probes are a feature of gas detection equipment that enable employees to check for gases including carbon dioxide, carbon monoxide, hydrogen sulfide, methane, oxygen, and other dangerous and combustible gases. These detectors need to be simple to operate. So that probe lines can be switched conveniently, rapid disconnects are frequently specified. Additionally, the aerospace, semiconductor, chemical processing, medical, and pharmaceutical industries use gas detection equipment.

Analyzing Blood Systems in Medical Industry

Blood testing equipment is used in medical laboratories to execute numerous diagnostic tests. These analyzers work quickly and continuously. Although internal connections are often secured in place, when a repair call is required, it may be necessary to immediately disconnect the machines from supply lines before disassembling them to conduct troubleshooting.

Analytical Methods

Purity tests for air and water are conducted using equipment. The composition of medications and other chemicals is also tested using them. The testing technique uses a lot of gases and liquids, and frequently the fluid lines need to be swiftly joined and disconnected without losing any gas or liquid.

Dental Techniques

Various types of tubing are used in dental equipment such dental chairs, drills, ultrasonic descalers, and anesthesia machines to transport water, compressed air, and anesthetic gases. When tools or parts of the machine need to be taken out for cleaning, maintenance, or sterilization, rapid disconnects considerably improve the functionality of the dental equipment. Quick disconnects increase hygienist and dentist productivity since connections don't need to be unthreaded and parts of a broken machine can be removed with ease when maintenance is needed.

Conclusion

In conclusion, rapid disconnects significantly increase user productivity by reducing the amount of time needed to establish and terminate fluid connections. When choosing on the material for rapid disconnects, manufacturers take the region of application into account. For each application, there are several quick disconnecting kinds and shut-off options to take into account.

The choice of material is crucial; especially if there will be large temperature changes or an aggressive fluid. To ensure that clients choose the appropriate quick disconnect model for any application, they may speak with the reputable manufacturers and suppliers indicated in this article's comment section.

Choosing the Proper Quick Disconnect Fitting Supplier

To make sure you have the most beneficial outcome when purchasing quick disconnect fittings from a quick disconnect fitting supplier, it is important to compare at least 5 companies using our list of quick disconnect fitting suppliers. Each quick disconnect fitting supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each quick disconnect fitting business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple quick disconnect fitting businesses with the same message.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services